Glass types

Starphire Crystal Clear Glass is created using silica sand with a low iron content during the glass-making to reduce standard glass’s otherwise characteristic green tinge, giving it a much clearer superior appearance. It provides maximum transparency and clarity by providing crystal clear glass, unlike the green tint usually found in standard float glass.

Standard Clear Glass is the glass type most often used in glazing applications. Visually, standard glass has a ‘greenish’ tint, most obvious when the panel is viewed from the side.

Australian Standards for Shower Screens

The Building Code of Australia requires Shower Screens and Shower Doors to comply with Australian Standards AS/NZS 1288 and 2208 and be made of Grade A toughened glass or Grade B wired glass.

The minimum thickness of framed toughened glass (Grade A) is 4mm. The minimum thickness of the partly framed and frameless toughened glass is 6mm.

At Infinity Glass, we use a high-quality 10mm toughened grade A safety glass for all shower screens. Our team is highly experienced and meticulous installers in compliance with Australian Standard AS1288.

Waterproofing

Suppose you are renovating, re-tiling, or building a new bathroom. In that case, we recommend purchasing your Custom Shower Screen early in planning your bathroom so we can assist you with ensuring your tiling layout and all structural supports are correctly positioned.

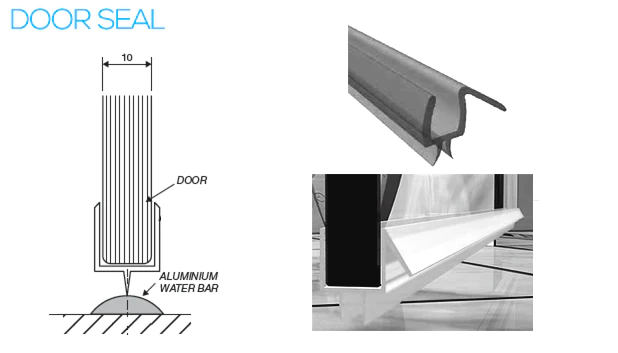

Door Seals: We provide a removable Plastic PVC Clear Water Seal to the underside of the door to seal the door panel of your Frameless Glass Shower Screen.

We also provide an Aluminium Polished Anodised Water Bar seal to the threshold of all custom installations.

Shower Rose position: All efforts should be made during design to ensure the shower rose is not positioned directly opposite the screen door.

Drainage: To ensure that no ponding occurs in the base, we recommend that the fall to the waste be a minimum of 15mm over a standard 1000mm base.

Panel & Door Sizes

Standard Door Width: Our standard door width is 600mm. Other custom widths are available on request.

Standard Panel Height: All Infinity Glass Frameless Glass Shower Screens are standard heights of 2000mm. Bath Screens are a standard height of 1500mm.

Hardware / Hinges

Custom Shower Screens: The default hardware supply for Custom Shower Screens is Solid Brass Polished Chrome unless stated by the customer during the Check Measure appointment before installation—other finishes are available on request.

Maintenance

Glass Maintenance

It is important to keep your glass clean. Glass that is neglected will accumulate water spots, eventually turning into mineral deposits.

The best way to keep your glass free of potentially damaging water spots is to squeegee the glass after every use. Regular cleaning will save you a lot of work if deposits are not allowed to accumulate.

Hinges and other hardware maintenance

The best way to maintain hinges and other hardware is to wipe them down after every use. When the hardware is kept clean, it will not collect mineral deposits that require using soap solution to remove. After your shower, use a dry towel to dry the hinges thoroughly.

Weekly cleaning is suggested if you cannot dry your hinges after every use. Use a mild soap, warm water mixture, and soft, non-abrasive cloth. After you have cleaned the hardware, rinse it thoroughly with clean, warm water and dry it.

Never use abrasive cleansers of any kind on hinges and other hardware. Many components are coated with a clear lacquer that will be irreparably damaged if subjected to harsh abrasive chemicals or scrubbing devices.

Frameless Glass specialist in Sydney.

Check out our wide range of glass offerings.

Let’s make things happen.

Our process is fairly straight forward. You talk, and we listen. Simple really. You’re in the driver’s seat. We’re here to help you find the way. If you need or want help to define and solidify what’s going to be the best option for your specific requirements, then we’ll do just that, help.

If you already know what’s what and you just want a seasoned professional to handle your job, then tell us what you need and let’s get started. Big or small, simple or complex, we use the best materials on the market and provide a level of service rarely seen in the tradie world.

What have you got to lose?